brinell hardness test discussion|brinell hardness test pdf : makers What is a Brinell Hardness Test? The Brinell hardness test is a widely recognized method for determining the hardness of various materials. It involves applying a constant load or force, . WEBRed is a vivacious, clumsy but, at times, misguided red head who trades her job in real estate for a new career as a Dolly Parton impersonator. Games. Apps. Movies & TV. Books. . Seriously Red. 2022 • 98 minutes. 50%. Tomatometer. family_home. Eligible. info. Add to wishlist. play_arrowTrailer.

{plog:ftitle_list}

webFacebook. 182,976,862 likes · 28,616 talking about this · 1 was here. Community Values We believe people can do more together than alone and that each of us plays an important role in helping to. Facebook. .

In this article, we have seen the Brinell hardness test and its two different methods – Standard and Non-Standard Brinell hardness tests. Also, discussed its advantages, disadvantages or limitations, and applications.

In this article we discuss the Brinell hardness test, we compare it to the Rockwell hardness test and discuss the advantages and disadvantages of both.What is a Brinell Hardness Test? The Brinell hardness test is a widely recognized method for determining the hardness of various materials. It involves applying a constant load or force, .The oldest of the hardness test methods in common use on engineering materials today is the Brinell hardness test. Dr. J. A. Brinell invented this test in Sweden in 1900. The Brinell test .

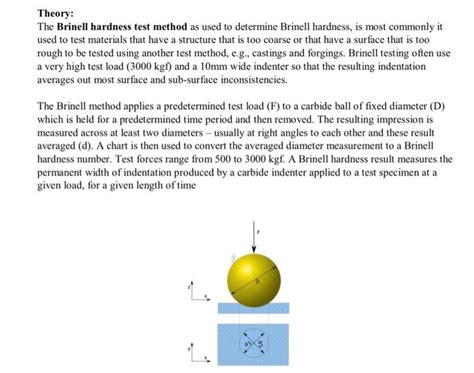

The Brinell hardness (BH) test measures the hardness of rock (kg/mm2) based on the displacement of a steel ball penetrating into a core sample exposed to a fluid over a certain .Brinell hardness testing is a commonly used method for determining the hardness of metals and alloys. The Brinell hardness test formula. When measuring hardness using the Brinell method, .The three principal tests used in determining the hardness of a material utilize Brinell, Vickers or Rockwell equipment. Hardness tests achieve a hardness value (dimensionless number) .Brinell testing of a material with different ball diameters and test forces must be conducted within the same force-diameter index ("Brinell test procedure") in order to enable direct comparison .

In today’s article, we explained to you all the information about the Brinell hardness test, formula, the importance of the Brinell hardness number and the advantages as well as disadvantages of this test.For Brinell hardness test. The hardness of materials are test by pressing a steel ball or tungsten carbide ball for a time of 10 to 15 seconds into the surface of specimen by a standard load F [kgf]. After that, the diameter of the indentation .ᅠ ᅠ ᅠ ᅠ ᅠ ᅠ ᅠ ᅠ ᅠ ᅠ ᅠ ᅠ ᅠ ᅠ ᅠ ᅠ ᅠ ᅠ ᅠ ᅠ ᅠ ᅠ ᅠ ᅠ Select Download Format Brinell Hardness Test Lab Report Discussion .

Brinell Hardness Testing 09/08/2014 10:07 PM Reference ASME Sec VIII Div 2 2011A- 6.7.6 Heat Treatment Requirements for Forged Fabrication and 6.1.2.3 Forming of Carbon and Low Alloy Material Parts. On conducting the hardness test on the various specimens composed, the Brinell Hardness Number was found to be the maximum for 2C composition i.e 7.5% Baggese + coir with loading condition below 187.5 kgf, 1C composition i.e. 10% Baggese + coir and 1D composition i.e. 10% Baggese + catalyst with loading condition above 187.5 kgf. We had a discussion at our local Clays field a couple weeks ago regarding shot hardness. What brought it up was the claim on a box of Remington Clay and Field shells of "high hardness shot". . You take the answer from that division and multiply it times 5( the Brinell hardness of lead) and that gives you the Brinell hardness of your shot . Brinell Indentation Diagram. In the standard method of the Brinell Hardness Test, we use 250 to 500 kg of load for soft material and 500 to 3000 kg of load for hard material such as steel and iron.

6 DISCUSSION / EVALUATION & QUESTION. . 6 Using your own word, explain the Brinell Hardness Test? 7 CONCLUSION - Make an intelligent conclusion of your experiment base on data and **discussion. Give examples in industrial application; Is this result a kind of contribution to knowledge?**

Sample Calculations: Brinell Hardness Test (1020 Steel) Brinell Hardness Number, BHN D = 10-mm P = 3000 kg d = 4.37-mm BHN = 190 Tensile Strength = BHN x 500 = 190 x 500 = 95000 psi Rockwell Hardness Test (1020 Steel) Rockwell Hardness Number, RHN RHN = 92.8 (Read for gauge on Rockwell Tester) Tensile Strength = 96071 (Found using Table II .LAB Report > Write (Discussion) on the Brinell hardness testing results as shown in the table & graph below: Note: include related mechanical properties as the shown in the results} Sample Reference (R) Recovery Stage (T1) Recrystallization Stage (T2) Grain Growth Stage (T3) Heat Treatment (Annealing Process) OC 300 Test Result 196.55 kgf/mm 206.53 kgf/mm 217.24 . What is this discussion about in one brief sentence? Select a category and describe a story. Create Topic . Community Discussions . The Brinell hardness test measures material hardness by determining the diameter of an indentation made by a hardened steel or carbide ball under a specific load. A load, typically ranging from 500 to 3,000 kgf .

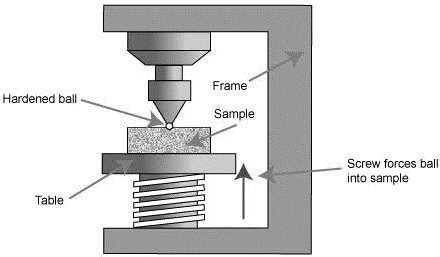

brinell hardness tester diagram

Mechanical engineering general discussion Forum; Yield Strength from Hardness Test. thread404-402228. Forum: . Brinell hardness has been shown to provide a strong relationship to ultimate tensile strength but not yield strength. . Hardness testing and the chemical check will only provide limited information to determine potential material .Discussion. The Brinell Hardness test is useful in determining which type of material should be used in different machines as it indicates their hardness. A practical use for that test would be to determine which type of metal or alloy to be used as train tracks and train wheels. You do not want the wheels to leave indents of the tracks .

General Discussion. Vintage Mustang Forum BOSS 351 Brinell test mark? Jump to Latest . Where did Ford perform the Brinell hardness test on BOSS 351 crankshafts? Mark . 1972 Mach 1 351CJ-C6-9" 4.11:1 Detroit Locker 1978 Chevrolet Corvette Red & Fast 355" s/b Yep, they're both fast & they get along too! Save Share. Like.

1.0 INTRODUCTION Vickers hardness test is also known as micro hardness test method. This method is based on an optical measurement system. The diamond indenter was used to make an indentation which is measured and converted to a hardness value. Vickers hardness test applied the same principle as the Brinell test. The load is applied for 10 .The data obtained by Brinell hardness test with the tungsten carbide ball “HBW” and non – standardized hardened steel ball “HBS” measured by 8 appraisers were compared by Youden plot, MSA, analysis of uncertainty, t-test and . Brinell’s Hardness test- Contact problem ; Brinell’s Hardness test- Contact problem . TAGGED: #ANSYSworkbench #ANSYS #StaticStructural, ansys. September 9, 2023 at 10:05 am Kariuki Karanja Subscriber Hello, . Edit Discussion

History Behind the Brinell Test. Let’s take a quick glance at the history behind the Brinell test. In 1900, Dr. J.A. Brinell invented this test. As an honor to him, the test named as a Brinell test. It is the oldest hardness test of all time. .Explanation: Brinell hardness test uses a hardened steel ball as an indenter. It is 10 mm diameter ball. Diamond indenter is used in the Rockwell test. 2. What test force is applied for nonferrous materials in Brinell test? a) 50 kgf b) 500 kgf c) 1000 kgf d) 3000 kgf View Answer.3. Type of Indentor used in the Three Different Scales of Rockwell Hardness Test. 4. Different Types of Hardness Testing Methods. 5. Size of the Ball to be used in Ball Indentor of Rockwell Hardness Test. 6. Di ameters of the different Balls used in Brinell Hardness Test. 7. Selection of Load in Brinell Hardness Test. 8.

5. Brinell Hardness Test • The Brinell hardness testing consists of indenting the test material with a 10 mm diameter hardened steel or carbide ball(10mm) subjected to a load of 500 to 3000 kg for 10 to 30 second. • The full load (3000 Kg) is normally applied for iron and steel for 10 to 15 seconds • The load can be reduced to 1500 kg or 500 kg for 30 second to avoid .Discussion 1. What are the advantages and disadvantages of Brinell hardness test. 2- Compare between the HB of the two tests of materials and what does this means? 3. Can all the materials be tested with the same kind of hardness test and with the same specifications? Discuss 4- Why is the ratio F/D’ used in the hardness test? (III) Theory: The Brinell Hardness Test is used to determine the Hardness Number of hard, moderately hard, and soft material E.g.: Brass, Br onze, Aluminum, Gold, and Copper.Rockwell hardness test is one of the static hardness testing methods using indentation depth as a measuring criterion. Basically, two types of indenter are used; one Diamond spheroconical (Brale) indenter with an angle of 120 O and a spher ical tip of 0.2mm; second is steel ball indenter with diameters as 1/16, 1/8, 1/4, ½ inches. .

much of the discussion in this standard refers to forces in kgf units. 1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. . 3.1.4 Brinell hardness test—an indentation hardness test using a verified machine to force an indenter (tungsten carbide ball with diameter D), under specified .

brinell hardness test theory

Brightness Color meter factories

2. Mention the method or instrument used for testing hardness, such as the Rockwell, Brinell, Vickers, or any other specific method. 3. Perform the hardness test on the sample, making sure to follow the specific instructions for the chosen method. Take multiple measurements for accuracy if required. 4.

For those velocities, a 10-15BHN alloy is all you need. I only need a massively HARD alloy like that for my .30-06 shooting at over 2200fps. Let's be clear about things: a 5-8 BHN alloy is soft, a 12-15BHN is hard, a 18-22BHN is type metal and WAY harder than you need for any reasonable handgun--and, if you need an alloy that hard, you will almost certainly be . Discussion. The comparison of hardness measurement results with those available in the literature is shown in Table 6. The cited authors used different values of the measuring force (120, 500, and 1000 N) and one measuring ball diameter (10 mm). . Hill, R.; Storåkers, B.; Zdunek, A. A theoretical study of the Brinell hardness test. Proc. R .

Protable Color Meter factories

brinell hardness test pdf

webClasificación y resultados de LaLiga Hypermotion de Fútbol. Calendarios, clasificaciones, resultados, fotos, vídeos y mucho más en www.abc.es

brinell hardness test discussion|brinell hardness test pdf